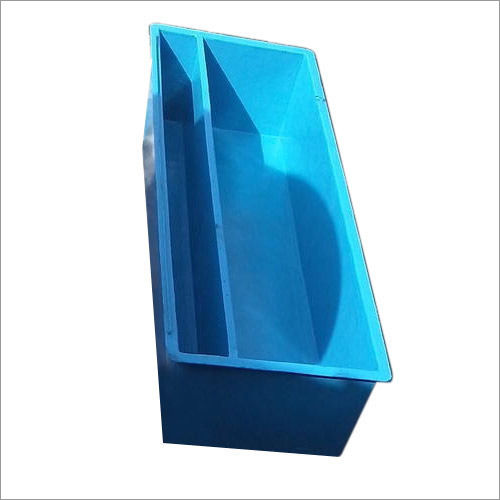

FRP Lining

Price 40 INR/ Square Foot

MOQ : 100 Square Foots

FRP Lining Specification

- Thermal Conductivity

- 0.2 0.3 W/mK

- Thickness

- 1 mm to 10 mm or as specified

- Density

- 2.0 Gram per cubic centimeter(g/cm3)

- Glass Type

- E-glass, C-glass, S-glass

- Shape

- Sheet, Lining, Customized shapes

- Coating Type

- Polyester, Epoxy, Vinyl ester resin

- Temperature

- -40C to 120C (depending on resin used)

- GSM

- 450-900 GSM

- Usage & Applications

- Corrosion resistance for concrete and steel, chemical process tanks, water proofing, sewage treatment plants, chemical process industries

- Material

- Fiberglass Reinforced Plastic (FRP)

- Application

- Chemical storage tanks, RCC roof, flooring, pipelines, ducts, scrubbers, industrial structures

- Technique

- Hand lay-up, Spray-up, Filament winding

- Surface Treatment

- Smooth finish/Matte finish

- Dimension (L*W*H)

- Customized as per requirement

- Fire Retardant Grade

- Available on request

- Bond Strength

- >2.5 MPa (to concrete substrate)

- Flexural Strength

- 250-430 MPa (depending on laminate structure)

- Impact Strength

- High (as per ASTM D256)

- Curing Time

- 8-24 hours (depends on resin type and ambient conditions)

- Color

- Grey, Blue, Green or as per requirement

- UV Resistance

- Good (with special topcoat)

- Hardness

- 70-80 Shore D

- Adhesion

- Excellent adhesion to RCC, metal, brick and other substrates

- Water Absorption

- <0.3% (ASTM D570)

FRP Lining Trade Information

- Minimum Order Quantity

- 100 Square Foots

- Supply Ability

- 1000 Square Foots Per Week

- Delivery Time

- 7 Days

About FRP Lining

Experience world-class protection with our first-rate FRP Lining solutions, meticulously manufactured for breathtaking durability and reliability. Available in Grey, Blue, Green, or customized shades, our affordable FRP lining is designed for high savings, offering exceptional water absorption resistance (<0.3%), superior impact and flexural strength, and excellent adhesion across RCC, metal, brick, and more. With outstanding UV resistance, fire retardant options, and a smooth or matte finish, this limited-time offering elevates safety for chemical storage tanks, floors, pipelines, and numerous industrial structures. Custom shapes and thicknesses available. Manufactured and supplied pan-India.

FRP Lining Unmatched Versatility & Advanced Features

Our FRP Lining delivers extra features such as high hardness (7080 Shore D), customizable thickness (110 mm), and multiple resin coatings like polyester, epoxy, and vinyl ester for enhanced performance. Available in sheet, lining, or tailored shapes, it caters to a wide spectrum of usagefrom waterproofing and corrosion resistance in chemical plants to robust flooring and ductwork. Competitive advantages include rapid curing, superior fire retardant grades, and excellent bonding with steel and concrete surfaces.

Secure Payment & Reliable Delivery of FRP Linings

We ensure transparent expenditure with straightforward payment terms and options. Goods are transported via secure shipping from major Indian ports (FOB), giving you peace of mind with every purchase. As reputable distributors, manufacturers, and suppliers, we primarily serve the main domestic market across India, providing prompt and dependable delivery. Your FRP lining orders are managed with care, ensuring safety and monitoring throughout the supply chain for optimal customer satisfaction.

FRP Lining Unmatched Versatility & Advanced Features

Our FRP Lining delivers extra features such as high hardness (7080 Shore D), customizable thickness (110 mm), and multiple resin coatings like polyester, epoxy, and vinyl ester for enhanced performance. Available in sheet, lining, or tailored shapes, it caters to a wide spectrum of usagefrom waterproofing and corrosion resistance in chemical plants to robust flooring and ductwork. Competitive advantages include rapid curing, superior fire retardant grades, and excellent bonding with steel and concrete surfaces.

Secure Payment & Reliable Delivery of FRP Linings

We ensure transparent expenditure with straightforward payment terms and options. Goods are transported via secure shipping from major Indian ports (FOB), giving you peace of mind with every purchase. As reputable distributors, manufacturers, and suppliers, we primarily serve the main domestic market across India, providing prompt and dependable delivery. Your FRP lining orders are managed with care, ensuring safety and monitoring throughout the supply chain for optimal customer satisfaction.

FAQs of FRP Lining:

Q: How is FRP lining applied to different types of surfaces?

A: FRP lining can be installed using hand lay-up, spray-up, or filament winding techniques directly onto RCC, metal, brick, and various substrates. Each project is customized to your structure and space requirements, ensuring a tailored fit and top-notch adhesion.Q: What are the primary benefits of using FRP lining in industrial applications?

A: FRP lining provides robust corrosion resistance, high impact strength, UV resistance, and waterproofing. These properties extend the lifespan of tanks, pipelines, flooring, and other structures while minimizing maintenance and repair costs.Q: When should fire retardant grade FRP be selected?

A: Fire retardant grade FRP should be chosen for environments with increased fire risk or where fire safety compliance is mandatory. This option is available upon request to provide enhanced protection for sensitive industrial applications.Q: Where can FRP lining be used within a facility?

A: FRP lining is ideal for chemical storage tanks, RCC roofs, floors, industrial pipelines, ducts, scrubbers, sewage treatment plants, and any area requiring heavy-duty corrosion or moisture protection.Q: What is the typical curing time and what factors affect it?

A: Curing time ranges from 8 to 24 hours, depending on the type of resin used and prevailing ambient conditions like temperature and humidity, ensuring a reliable and quick installation.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Fiberglass Acid Tank Category

Fiberglass Acid Tank

Price 15

Minimum Order Quantity : 20000 Liters

Application : Industrial

Material : FRP

Surface Treatment : Smooth

FRP Lining Tank

Price 72500 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Water storage and chemical processing

Material : FRP (FiberReinforced Plastic)

Surface Treatment : Internal lining treatment for corrosion resistance

FRP Lining Tanks

Price 21000 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Chemicals

Material : Chemicals/Oils, Water, Waste

Fb Acid Tank

Minimum Order Quantity : 1 pices

Application : Industrial

Material : FRP

Surface Treatment : Smooth

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese